Robert Paxton McCulloch was a skilled Stanford University engineering graduate who inherited a considerable sum of money from his multi-millionaire grandfather at an early age. This gave him the financial freedom to indulge in two of his passions, boat racing and engineering, which eventually led to him becoming a national champion in classes C and D of outboard hydroplanes in the1930’s, and the also saw him set up a machine shop, where he and his helpers made engines for midget racers, and ended up building a twin motored, four wheel drive, midget that was so fast that it resulted in the ban of this type of midget from the tracks. Search for more speed resulted in him using his inheritance to set up the McCulloch Engineering Company in which he employed a team of engineers to develop engines and superchargers for aeronautical and automotive applications.

90 HP 60 Cubic Inch Engine (courtesy of Richard McCulloch)

The first product of the McCulloch Engineering Company was a 2 stroke 60 cubic inch 90 HP racing engine developed by Robert P McCulloch, Gerald C Robechaud and Milton Hoeppner. Another product developed at McCulloch Engineering by Francis L. Colburn was a centrifugal supercharger for the flathead Ford V8. The flathead Ford V8 was an enormously popular powerplant at the time, and a low cost centrifugal supercharger developed for this engine had potential for high sales. The resultant supercharger was belt driven, was horizontally mounted between the standard intake manifold and carburetor, and may well have been one of the first aftermarket blower systems produced.

The 1937 McCulloch Supercharger

McCulloch Engineering Company was based in Milwaukee, Wisconsin and the flathead supercharger unit was manufactured and sold between 1937 and 1940, and was significantly different to the later McCulloch blow through centrifugal superchargers in that it was an inline unit, which compressed and mixed the fuel/air charge. It consisted of an impellor, which turned at six times the engine speed in the impellor housing, and was driven by a set of worm gears mounted on the drive shaft and rotor shaft. The worm gears were driven by a triple pulley mounted an input drive shaft driven from the crankshaft pulley using several belts and were initially lubricated using engine oil under pressure from the engines oil system. By revolving at high speed the impellor caused the fuel/air mixture to build up pressure, up to a maximum of four pounds, within the impellor housing as a result of centrifugal force, and the pressurized mixture was discharged into the inlet manifold. There appears to have been two versions, one without a water jacket, and the other with a water jacket around the impellor housing which was used to warm the air/fuel mixture and was purported to aid low speed performance. A special three/four belt crank pulley was furnished for the Ford crankshaft, two new water pumps with three belt pulleys, as well as a set of matched V belts, a belt idler pulley and a special air cleaner which was required due to the reduced clearance added by the supercharger. The initial units, manufactured in 1937 and retailing for around $85, were designed to bolt onto the existing Ford and Mercury V8’s which had the water pumps attached to the cylinder heads. Continuous improvement by the McCulloch engineers resulted in a modified version being introduced in 1938, retailing for $125, and which was also engine oil lubricated via a supplied intake manifold, which contained all the necessary link ups required for the engine oil lubrication. These also appear to have been offered with in water jacketed and non water jacketed versions. In 1939/40 thermostatic control of the exhaust gas through the impellor housing was introduced, in order to promote a rapid warm up of the fuel/air charge output from the blower. These flathead superchargers were designated with a model number that correlated the year of manufacture against the intended application vehicle (M for Mercury and F for Ford). Hence 38F refers to a 1938 model intended for a Ford.

The supercharger, which may also have been used as OEM on the Graham-Paige, was purportedly popular with Truck owners due to the increased torque and low atmospheric pressure performance that it gave. McCulloch advertising of the period claimed a 38% increase in Horsepower, better gas mileage, smoother performance and a longer engine life. More than 5,000 of the superchargers were sold during the late 30’s, but production was discontinued during the early 1940’s due to two reasons. The impeller for the supercharger, being gear driven, and being lubricated via the engine oil system which was often not changed as regularly as it should, had a tendency to become quite noisy with wear, and the blower, due to it’s fixed ratio of 6:1, produced no significant boost until high rpm was being achieved by the engine with boost levels being no more than 4 psi, even with radical reworking. These facts failed to impress the general public, and sales were low, although by the early 40’s this had became irrelevant as McCulloch was making superchargers for all purposes, and many thousands were manufactured for military equipment used during the Second World War. In fact McCullochs total sales in 1942 were $3 million, and the only larger manufacturer in the supercharger field at that time was General Motors.

The success of McCulloch Motors, and the restless nature of Bob McCulloch, resulted in him selling McCulloch Motors to Borg Warner in 1943 for $1 million , which was subsequently invested in Pan American Airways stock. Six months later some of the stock was sold off and Bob McCulloch set up McCulloch Aviation Incorporated to manufacture 6,000 drone plane engines for the, based upon earlier lightweight two-cycle engines designed by McCulloch, for the Army Air Force. As a result of this contract McCulloch felt that his future lay with featherweight two-cycle engines for Industrial use, and given that it was time for a change, and his current manufacturing facilities were not suitable, McCulloch uprooted McCulloch Aviation and moved it to California.

VS57

The move was made in 1946, and Los Angeles was picked due to low manufacturing costs and the availability of skilled mechanics. A fifteen acre piece of land was purchased opposite the airport and some old barracks set up to serve as offices and plant buildings. As well as Bob McCulloch and his family, a further 33 families of McCulloch Aviation employees made the move to Los Angeles, and as a part of the relocation Bob McCulloch bought 13 houses and 16 apartments to house these employees. Initially during 1946, whilst the 80,000 square foot factory was being built, old barracks buildings were used to house the offices and plant. Many of these had leaky roofs and probably did not create a very good impression when Henry Kaiser arrived with his retinue to enquire about a two cycle automobile motor, however they did serve the purpose and within 60 days of setting up the first engines (lawn mower and chain saw) were being produced out of these buildings, along with other staple items such as die-cast gas heaters.

The new McCulloch Motors Inc. factory in Los Angeles

The factory was completed in 1946 , costing around $1 million, and McCulloch Aviation became McCulloch Motors Corporation, and after evaluation of the product line Bob McCulloch dropped the heaters and development work for the Kaiser-Frazer two-cycle opposed piston engine, and decided to concentrate on the lawn mower and chainsaw engine product lines. These were built by McCulloch Motors Corp. and were supplied to Sears, Roebuck and Reed-Prentice respectively, and after extensive research by McCullochs engineers (and Vice-presidents) John Ryde and Gerald Robechaud, McCulloch found that he would could produce a better and lighter chainsaw by himself. As a result of this development McCulloch produced his first chainsaw the 5-49, which was 5Hp and weighed 49 pounds, was two-thirds the weight of it’s nearest rival, and cost $50 less, and sold in such volumes that McCulloch Motors 1947 sales of $4 million increased to $40 million by 1951, and a $2.5 million plant expansion was made in 1950.

This expansion led to McCulloch Motors producing helicopters and gyro-copters, as well as more interestingly setting up Paxton Engineering on May 1st 1950 to research new product lines which would allow the continuous expansion of McCulloch Motors. Initial projects for Paxton Engineering were the MI-15 portable pump and subsequently a series of smaller pumps, although by mid 1951 Paxton Engineering was tackling the design of a new and improved supercharger.

The concept of a cheap, bolt on aftermarket supercharger for the general public was never dropped by Bob McCulloch and extensive research was carried out by Paxton Engineering (who changed fairly quickly to Paxton Products) to produce a system which would deliver a significant amount of boost at low engine rpm without subsequent high impellor speeds at high engine rpm. The system was required to have the service requirements of the automobiles it was to be fitted on, and should to be quiet in operation and retailed at low cost. Manufacturing and installation requirements specified that one supercharger model could be fitted to a variety of vehicles, and that lubrication was internal to minimize contamination.

The VS57 was the result of over $700,000 being spent in research and development in an effort to meet these requirements, and was made possible by the elaborate multi-section magnesium die casting production methods developed by Gerald Robechaud . The VS57 was first produced in 1951 in limited numbers, and was extensively road tested in California for two years before being marketed to the public in 1953. The VS57 was driven using a V shaped belt and used a unique Variable Speed (VS) drive pulley in conjunction with an idler arm to generate high boost at low engine rpm. The flanges of the supercharger pulley were designed to have a variable separation, which was used cleverly in conjunction with input shaft speed multiplication via a planetary ball drive, to vary the impellor speed across the engine rpm range. At low engine rpm belt tension separates the flanges of the input shaft pulley and drives the input shaft at a 1:23 ratio to the crankshaft pulley. At high engine rpm the boost produced is regulated to 5 pounds and boost is used to force the input shaft pulley flanges together, causing the belt to rise, and the input shaft to be driven at a ratio of 1:13 to the crankshaft pulley. The actual input shaft ratio changes gradually between 1:23 and 1:13 as the closing flanges overcome the tension of the idler pulley. The planetary ball drive multiplies the input shaft speed by 4.4 to 1 to produce high impellor speeds, thus producing boost. A kick down set up is incorporated which forces the blower into high boost when there is a sudden power demand, and this is governed by a solenoid switched via inlet manifold vacuum, which drops on high acceleration. Lubrication was achieved by a cam driven oil pump mounted on the ball driver shaft which was immersed in an internal oil reservoir.

The VS57 met all the requirements that were initially specified. It could produce high boost at low rpm due to the kick down setup and speed multiplication achieved by the planetary ball drive. The planetary ball drive was quiet in operation and lubricated using an internal oil supply of automatic transmission fluid. It was designed to blow boost through carburetors in place of the existing air filter, and could therefore be bolted on any engine, providing there was sufficient room underneath the hood. Manufacturing costs, and subsequent retail prices, were relatively cheap due to the use of die cast stampings, and the fact that it was a single reusable product line.

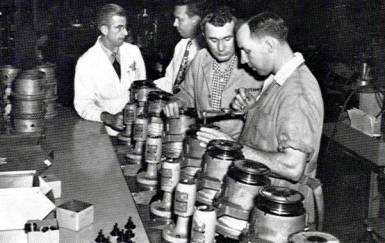

Assembly line January 1954 and Open day visitors October 1953

The VS57 was officially unveiled to the Motoring press in September 1953 via a conference at the McCulloch Motors site. McCulloch vice president C. Fred Breer briefed representatives of the press and national magazines on the design and performance capabilities of the supercharger. After the briefing they were allowed to conduct test drives of a range of McCulloch equipped vehicles. The press response was favourable and many magazines subsequently reported on the supercharger, with the Los Angeles dailies leading the way with reports the day after the conference.

The attractive side of press conferences

Initially the supercharger was only available for 1950 through 1953 Ford cars, although fast gearing up of mass production in October 1953 resulted in the kit range being extended to cover very nearly every commercially available V8 and straight 6 engine in early 1954. As well as manufacturing the supercharger McCulloch Motors also set up an installation shop so that initial owners would benefit from proper factory installations and consequently avoid bad early publicity whilst the dealer network was being established and trained up. McCulloch employees were given a 35% discount off the price of the supercharger kits, although the discount did not include the installation cost.

The VS57 supercharger was formally presented to the SAE on January 15 1954 at Detroits Sheraton-Cadillaac hotel to a convention audience of some 500 automotive engineers. The presentation was by John W Oehrli and consisted of prepared text, coloured movies and slides followed by a brief question and answer session. Earlier demonstrations to the Kaiser-Willys corporation had sufficiently impressed them with the VS57 supercharger to cause them to shift it as standard on the Kaiser Manhattan installation of their 6 cylinder 226 cid engine in 1954, albeit labelled as a Kaiser supercharger. This was publicly announced in late January 1954 in the wake of the SAE meeting and its debatable that the Kaiser-Willys adoption of the supercharger effectively killed off any interest by the majors.

The Supercharged Kaiser Manhatten

The Kaiser installation used a maximum boost of 4 pounds to increase the output of the engine to 140 bhp, allowing the outdated engine to remain competitive, and was apparently well suited to the Kaiser engine due to the torque/hp characteristics of the engine. Anywhere up to 5,440 supercharged Manhattans were produced between 1954 and 1955, and Kaiser also used the VS57 on a few Darrin’s with the actual number of supercharged examples built believed to be just 3. A further 1021 Manhattans were built for export to Argentina and are believed to have been unsupercharged, except for 6 Manhattans which remained behind in the US and were fitted with superchargers. Unfortunately, as is well documented, the supercharged engines were not enough to save Kaiser from extinction in 1955. Packard, also in 1954, used a VS57 supercharger on their show car, the Packard Panther. This was a fiberglass bodied sports car based on a 122” wheelbase with a 359 cid straight eight power plant providing 275 bhp with the McCulloch installed. Five of these unique cars were built, and they are particularly notable due to one example being timed at 131.1mph at Daytona in 1954, making it the fastest in it’s class at that time.

Further local publicity was achieved in May 1954 when the KTLA TV station transmitted a hour long show about the VS57 supercharger. The show which was titled ‘City at Night’ and which covered night time activities in Los Angeles started at 10 pm and tracked supercharger production from Die casting through final assembly, and featured on-the-job interviews with McCulloch employees and management. The telecast opened with Fred Breer explaining the advantages of the supercharger for overtaking and altitude driving, and then for the main part consisted of vice president Sherwood Egbert talking through the production process. The close of the show featured presentations by John Oehrli and John Thompson.

National publicity for the supercharger was mainly achieved by single page adverts in some of the motoring press in early 1955, and by an ongoing column written by John Thompson in Motor Trend which was first published in November 1955. This detailed achievements of the VS57 supercharger and also listed dealers as and when they started conducting McCulloch installations. This column actually ran through to March 1958 when Paxton changed ownership and extracts from the column.

The VS57 enjoyed steady sales as an aftermarket performance accessory during the mid 50’s, although these sales never met the production capability of 5,000 units a month that the McCulloch factory had. Studebaker were the next major manufacturer to adopt the VS57 in 1957. The Studebaker Speedster had previously been offered with the VS57 in 1955 by an enterprising Los Angeles dealer, as a $390 option, but this cannot be counted as a factory production. Studebaker offered the VS57 installed on the Golden Hawk with the supercharged 289 cid engine producing 275 bhp, equaling the output of the previous years heavy 352 cid engine, and giving the Studebaker a reputation as a performance vehicle. Supercharged Golden Hawk production continued into 1958, with the total 1957/58 manufacture being 5,234 units. A total of 4,809 supercharged 289 cid Packard Clippers were produced in 1957, these being re-badged Studebakers. A further 588 supercharged 289 cid Packard Hawks were produced in 1958 before the doors finally closed at Packard. Once again the VS57 was associated with the demise of an automobile manufacturer (but hopefully not the cause!). Ford also retailed the VS57 in 1957 as a dealer installed power pack option, which reputedly resulted in a few dual quad and triple deuce configurations as well as standard single four barrel configurations.

1957 Studebaker Golden Hawk

Total production of the VS57 during the 50’s is believed to be in excess of 46,000 units, which gives an indication of the popularity of the unit, as it was quite an expensive accessory for a car of the period. The VS57 did however gain a reputation for being unreliable. Owners of high annual mileage vehicles often neglected servicing of the superchargers, which with the 3,000 mile servicing requirement of the VS57, often caused failures. The Hot Rodders of the 50’s also caused high failures of the superchargers, either by running at full boost all the time resulting in overheating, or with the use of oversize crankshaft pulleys and high revving engines to produce higher impellor speeds and higher boosts. However to balance this many thousands of vehicles during the 50’s ran well serviced VS57’s for thousands of miles without any problems whatsoever.

VR57

Supercharger manufacture and development was not restricted to the VS57 and Paxton Products were actively involved in researching new designs of superchargers. One significant early product that Paxton Products developed was the supercharger used on the Novi cars raced at Indianapolis. These were engine oil cooled conventionally mounted superchargers which were gear driven at a ratio of 5 ¼ to 1 and had impellor speeds of up to 40,000 rpm. The supercharged Novi V8 engines were capable of producing up to 650 hp from 180 cubic inches, however power is not everything and they were generally unsuccessful in racing, although this was not attributable to the supercharger. The Novi name, and it’s connection with Paxton, still lives on today as Paxton Automotive currently produced high output gear driven Novi superchargers.

The direct oiled Paxton Novi

Paxton Products even developed roots type blowers, although these never went into production on a volume basis they could occasionally be seen at the drag strip. A one off McCulloch roots blower was run by John Bandimere from Denver, Colorado, on his 55 Chevy at the 1955 national Drags and apparently ran sizzling times.

Another product that Paxton Products designed during 1955, and developed during 1956 was the variable ratio supercharger. This was developed to provide a general purpose supercharger that was more compact, and easier to install than the VS57, and also had greater boost and air flow handling capabilities. The resultant supercharger, which is commonly known as the McCulloch-Paxton VR57 differed from the VS57 superchargers in that instead of the planetary ball drive being a fixed ratio, and the drive pulley being a variable ratio, the planetary ball drive had a variable ratio, and the drive pulley had a fixed ratio. Another more significant difference, which no doubt benefited from Paxton’s involvement with the Novi, was the use of engine oil for lubrication and cooling.

The variable ratio planetary drive was achieved using split inner and outer ball races that varied in separation according to the input shaft speed. At low engine and input shaft speeds the inner ball races are pressed together with springs, forcing the balls between the races to ride higher and forcing the outer ball races apart, giving an impellor ratio of 3.5 to 1. At higher engine speeds, engine oil pressure forces the outer races together via a piston, forcing the balls into a tighter circle and giving a ratio of 5.5 to 1. This ratio varies between 3.5 and 5.5 to 1 against engine speed due to engine oil pressure gradually overcoming the spring pressure against the inner ball races. A supercharger drive pulley ratio of between 1.7 and 2.0 to 1 allowed the supercharger impellor to be driven at ratios of up to 11.0 to 1, which, as for the VS57 units would allow impellor speeds in excess of their rated 32,000 RPM maximum. To limit the impellor to it’s maximum, boost output from the supercharger was used to reduce the oil supply to the split races, allowing the planetary drive to drop back into low ratio as engine speed increased. Interestingly the impellor is the only component that is common to both VR and VS superchargers.

As with the VS57 the VR57 could be forced into hi ratio, and in this case this was achieved using a throttle activated valve which diverts the oil supply direct to the piston acting on the outer ball races, thus increasing oil pressure on the outer race. This was also regulated by the increasing boost pressure as the boost output of the supercharger increased.

The use of the variable planetary drive arrangement in the VR57 eliminated the need for the variable ratio pulley and tensioned idler arm set up used in the VS57. In the case of the VR57 a conventional supercharger drive pulley could be used in conjunction with an adjustable idler pulley for applying tension to the drive belt. This elimination of the idler arm and variable ratio drive pulley allowed the VR57 to be slimmer in profile than the VS57 unit, although it’s diameter was slightly larger, in order to accommodate the larger drive balls and races required to give the variable ratio planetary drive. This slimmer profile reduced the installation requirements of the supercharger, and allowed for more compact installations, minimizing the need for fan blades and radiator re-positioning . The use of a standard drive pulley on the supercharger input shaft also provided the added bonus that standard ½” drive belts could be used in conjunction with standard crankshaft and idler pulleys, allowing for an easier installation by the home mechanic when bought as an aftermarket kit, and again offering minimized clearance problems.

Ford, at that time were looking for a means of increasing the performance of their racing engines as a part of their long running NASCAR battle with Chevrolet. With the Rochester Fuel Injection looming on the horizon Fords prospects looked weaker for 1957 and they were looking at all options. The decision to use superchargers was made late in 1956, and the decision to use McCulloch superchargers was probably due to the fact that Ford did not yet have a system of their own, and the fact that McCulloch superchargers were well proven in the field. Former Indy driver Peter DePaulo is often credited as being the person who suggested McCulloch superchargers to Ford in late 1956 however Ford was certainly already aware of McCulloch at that time, indeed one of the rumors that came from Detroit in 1955, and was reported in the Sept 1955 Motor Life magazine, was that the 1956 Ford Thunderbird would appear with either fuel injection or a McCulloch supercharger. McCulloch themselves reported in 1955 that Benson Ford had driven a McCulloch powered Thunderbird and was very impressed, and also reported in early 1956 that more than 50% of the VS57 supercharger installations were to Ford Thunderbirds. Regardless, at some time in 1956 Ford were shown the direct oiled VR57, which would have been at, or near, the end of it’s development life, and ready for production, and were sufficiently impressed that they wisely engaged McCulloch’s Paxton Products for an exclusive one year contract for the VR57.

The 1957 homologation rules for NASCAR stipulated that only factory stock” engines could be raced during 1957. Factory “stock” was defined as being advertised as a regular production option, and also required a minimum of 100 power plants being manufactured prior to the start of the race season, 1 January 1957. To meet these homologation requirements 100 – 125 VR57 units were delivered to Ford in December 1956, as a result of intense effort at Paxton . These were Phase I units, i.e. pre-production units, which differed from the later Phase II units. The Phase I blowers were sensitive, and suffered with unreliable control valves, although their performance was reputed to be a lot higher than the later Phase II blowers. They were also apparently tedious to work with, however they were never meant for use by the public, so this was tolerated. The most obvious difference with the Phase I is in the design of the case, which lacked the ribs of the later unit and used a large clamp instead of screws to hold the two parts together. Ford produced a total of 12 “D” coded 1957 Thunderbirds in January 1957, and an unknown number of 1957 passenger and convertible cars using these first phase I VR57 units, which incidentally had serial numbers beginning with the designation VR57A, or Ford experimental serial numbers.

With the homologation requirements met, further supercharged Ford production was not scheduled until later in 1957 when the Phase II VR57, a which produced nearly the same boost levels as the slightly larger Phase I units, were used. These were nearly as potent as the earlier Phase I units, and proved to be a lot easier to maintain and repair. The actual number of supercharged Fords produced in the Phase II production runs, are unknown, although between 208 and 211 of this production is believed to have been in the form of Thunderbirds, and a similar number (maybe as many as 300) were produced as Fords. All of the Phase II VR57 equipped Ford engines were designated as F code engines, and power outputs were 325 Hp @ 4,800 rpm or 340 Hp @ 5,300 rpm dependant upon the installed cam (256 or 290 degree duration), although Ford conservatively claimed only 300 Hp. Interestingly Paxton Products claimed that the output was actually 360 hp with the hotter cam.

The VR57 equipped Fords basically dominated Motorsport during early 1957, and if it wasn’t for the NASCAR ban on the use of superchargers (and fuel injection) from racing in April 1957 would probably have continued dominating for the rest of the season. A supercharged Ford even held the NHRA National title for three years. However, as happens with all good things, the use of superchargers was banned from NASCAR racing in April 1957. Ford was the only company out of the big three who honoured the AMA ban on high performance in 1957. This was a gentleman’s agreement that member companies would disband all involvement in racing and eliminate all references to horsepower from advertising.

The one year agreement with Paxton Products for the VR57 ended in September/October 1957, and on 1st November 1957 Paxton publicly announced that the VR57 would be available, with the serial number prefixed VR-57B, either without installation kit for $295.00, or with an installation kit for $495.00, for 352 cid 1958 Ford and 361 cid 1958 Edsel installations only. In actual fact the installation was the same for both engines, with only the scroll rotation being different between them. Paxton also announced that they did not intend to produce the VR57 to back-fit 1957 or earlier automobiles, with the possible exception of a few isolated models such as the Chrysler 300C and the 1957 Corvette. Instead they would continue offering the VS57 unit for general use. The VR57 actually had a greater air flow capacity than the VS57 units so I guess Paxton reserved the VR units for the newer larger V8 units being produced, which would have otherwise exceeded the capabilities of the VS57 units.

Paxton actually had a policy of using existing components during installation, in order to minimize cost. So many VR installations by Paxton used VS57 idlers, pulleys and brackets, and the supercharger drive belts could either be the standard McCulloch 7/8 inch belts, or in some cases ½” belts. As for the VS57A units intended for Thunderbirds, Paxton stamped a letter at the end of the serial number indicating the intended application, if it wasn’t the standard Ford installation, i.e. CH for Chevrolet. Additionally the VR57B serial numbers did not continue on from the VR57A serial numbers, instead they started from 1 again.

Paxton Products produced the VR57 superchargers in limited numbers through the rest of 1957 and early 1958. Why production was limited was unknown, although the supercharger requirements of Studebaker and Packard, coupled with strong aftermarket sales of the VS57 units may well have heavily utilized Paxton,s production capacity. Servicing problems also existed with the VR57 units, basically because Paxton did not generate sufficient service information for these superchargers, and consequently from mid 1958 Paxton required all VR Superchargers to be returned to them for any warranty claims or rework.

Paxton introduced further improvements for the VR units during 1958. These improvements included high quality inner and outer races, Swiss steel balls, upgraded multiplier springs, and improved rear oil seal ring and the addition of an air deflector shield to deflect the boost output from the rear oil seal. The new VR units had serial numbers which started with the prefix VR58 and they were supplied by Paxton with a 4,000 mile, or 90 day warranty, which was valid only if the unit was not operated in excess of 5500 rpm with a standard 7.7 inch diameter crank pulley, and if the unit was not modified to generate more than five pounds of boost. As a reminder of this warranty the VR58 units were tagged with a warning that tampering with the boost pressure would invalidate the warranty. An optional oil filter, which greatly improved the superchargers life, was made available at the time of the VR58 introduction, basically as a safeguard against contaminated oil entering the supercharger. The VR58 was offered for the 348 cid 1958 Chevrolet, all 1955-58 Corvettes, the 1957-58 Chrysler 300, and the 1958 Fords, Edsels and Thunderbirds. Paxton fully intended that the VR58 supercharger would be available for all 1959 models however the continued popularity of the VS57, due to it’s higher boost levels at low rpm’s and the development of it’s replacement, the short lived DO-VS59, stopped all further development.

DO-VS59

During 1957 Anthony, Vincent and Joseph Granatelli moved down from Chicago to Los Angeles, after selling their successful speed shop Grancor Automotive Specialists. The Granatelli brothers had extensive experience with McCulloch superchargers after modifying several for racing and installing hundreds at Grancor, and they joined up with John Thompson, the chief engineer at Paxton, to try and resolve some of the problems that the VS57 suffered from. Their collaboration, and confidence in the results, resulted in them purchasing Paxton Products from the McCulloch Motor Company in 1958 and resulted in them developing the DO-VS59.

The VS57 was suffering from quality control problems during manufacture, and was becoming increasingly expected to perform at and above it’s design speeds due to the larger capacity and higher revving V8’s coming onto the market, as well as due to the requirements of racers. The quality control problems were mainly due to the steel balls in the planetary drive, which have to be matched to a fine tolerance to prevent imbalanced loading and subsequent wear during operation. These were being supplied to the factory in matched tolerances but were being mixed in hoppers during the manufacturing. The internal oil pump was also flawed in it’s oil pickup design, and was providing insufficient lubrication for the planetary drive. It had an inadequate capacity for high speed lubrication and it’s heavy plunger floated at high rpm’s, starving the balls and races when they needed lubrication the most. Failures as a result of these was giving the McCulloch a bad name and resulted in large numbers of warranty claims due to premature failure, and possibly contributed to the discontinued use of McCulloch superchargers by Studebaker. Some of these faults were corrected on the VS57, but more modification was required to allow the units to run at higher input speeds.

The research by the Granatelli/Thompson collaboration found that the planetary drive steel balls were also a significant contributory factor in the speed limitations of the VS57. Friction of the planetary drive balls on the races generates heat during the normal operation of the supercharger, with this heat being absorbed by the lubrication fluid. As the input shaft speed increased above the design limit of 5200 rpm the centrifugal force on the balls, and the extra impellor load, caused the balls to slip on their inner race, generating excess heat with subsequent overheating of the lubrication fluid and galling of both the race and balls. The use of a wider contact path between the balls and their race was proven to lessen the slippage, allowing a higher rpm operation, but a wider contact path also results in more heat being generated.

The DO-VS59

The use of the engines high pressure oil supply to lubricate and control the VR57 superchargers had resulted in the VR57 superchargers running significantly cooler than the VR57 units. The Granatelli’s and John Thompson, as a result of earlier research into engine oiling, made the decision to use direct engine oiling on the VS57 to allow the unit to run cooler and to completely remove the problems associated with ensuring adequate lubrication of the balls and races. The resultant extra heat capacity also allowed them to increase the contact path of the planetary balls on their races, and allowed them to use a stronger spring loaded pressure plate which kept the bearing races against the balls, thus reducing slippage. The resultant unit was the McCulloch DO-VS59 (DO for Direct Oil) which was introduced in 1958. The casing that was used on the VS57 was modified slightly for the DO-VS59 to allow the use of direct oiling. The dipstick opening now served as the inlet for the oil feed from the engine which was fed straight to the hollow input shaft, and consequently straight onto the units planetary drive. An outlet was added at the base of the supercharger to allow the oil to return back to the engine, relying on gravity to feed. The internal oil pump was replaced with a stainless hose which carried the pressurized oil direct from the former dipstick housing to a modified ball driver shaft which delivered the oil to the planetary drive and the other lubricated components.

The DO-VS59 (which was always marketed as a McCulloch and not a Paxton-McCulloch) was only volume produced for about a year and was offered with a 100% guarantee for the first 90 days or 4000 miles, and a 50% guarantee for the next 270 days or 12000 miles total. Andy Granatelli’s confidence in the product was such that he completely dropped the VS57 unit, and in a bid to stimulate DO-VS59 sales killed all VS57 support (with the exception of service parts) and pushed the DO-VS59 as a part exchange unit rather than rebuilding VS57 units. The DO-VS59 was poorly tested however, and consequently not a great success as owners either failed to change the engine oil at the required intervals, or added substances to the oil (such as STP) which were not compatible with the bearings and seals used in the units. Reliability was further compromised by the fact that acids generated as a result of the build up of blow by gases could corrode the ball drives and races, particularly if the supercharger units were left standing for more than a couple of weeks.

SN60 and Beyond

The McCulloch DO-VS59 superchargers were manufactured and retailed right through to 1962 (and possibly later) alongside the SN (Short Nose) series superchargers that Paxton introduced in 1959. Further research at Paxton resulted in the introduction of a more efficient fixed ratio supercharger, which used the planetary drive arrangement of the McCulloch VS superchargers and was marketed as the Paxton SN60. This lacked the variable speed of it’s predecessors, which was proving to be a liability due to belt slippage at the higher engine rpm’s it was expected to be driven at for the newer higher revving engines. The removal of the variable ratio drive resulted in the supercharger being 2.2 inches shorter than its predecessor, hence the term ‘Short Nose’.

Paxton also returned once again to the use of an internal oil reservoir eliminating the corrosion and lubrication cleanliness problems that had plagued the DO-VS59 units, and to a lesser extent the VR57/58 units. Technology improvements to bearings, seals and lubrication gave them greater power handling capabilities and reliability than the earlier McCulloch units. Significantly a redesigned oil pump which had an increased capacity, and which didn’t suffer from float at high rpm, allowed the SN60 blowers to be turned at higher rpm’s than their predecessors without risk of oil starvation to the drive bearings.

The SN60

As well as producing the superchargers Andy Granatelli also raced SN60’s using Chryslers, Plymouths and Chevrolet Corvairs with single and dual blower set ups during 1960 and 1961 and set numerous speed records. A switch to Studebaker in 1962, along with more successes resulted in Studebaker purchasing Paxton Products, and employing the Granatelli brothers with Andy Granatelli eventually becoming president of Studebakers STP division, and Vince and Joe Granatelli remaining with Paxton. The feedback from racing with the superchargers resulted in the SN62 being produced, and the Studebaker ownership of Paxton in conjunction with the fact that Studebakers president was former McCulloch Vice President Sherwood Egbert, resulted in the extremely fast SN supercharged Avanti’s being produced.

The VR58 was still offered by Paxton as a replacement unit through to the mid sixties, and was also offered through to 1970 in a modified form as racing supercharger. This variant (the VR5?) had the variable ratio planetary drive fixed in the high ratio via use of an adaptor, the oil control valve was replaced by an aluminum stud, and the supercharger was intended for drag racing usage only, retailing for about $250. The boost output could be modified (as is the case with all the VR units) by replacing the standard drive pulley with a different sized one.

After splitting with Studebaker Paxton dropped out of the supercharger business in 1974 (probably due to emission legislation effectively killing off the performance maerket – albiet temporarily), concentrating instead on centrifugal blowers for industrial and marine applications. Ironically the VR supercharger survived this and was reworked as a blower for moving air through the cabins of submarines. These units had oil reservoirs mounted on the bottom, and were completely reworked as single speed blowers, producing a high volume of air at a low pressure of about 3 pounds.

Public demand persuaded Paxton to re-introduce the SN60 in 1979, and since then Paxton has modified and upgraded the SN60 through various variants (SN90, SN92, etc.,) to it’s current SN2000 guise. To all intents and purposes these ball drive units are basically the same superchargers as the earlier VS57 units, and consequently many parts from these later units are interchangeable with the earlier units. Paxton also introduced an advanced gear driven Novi supercharger in the late 90’s. and no doubt the Novi name was used in tribute to the early 1950’s gear driven superchargers developed by Paxton for racing at Indianapolis.

Whilst the Granatelli brothers remained with Paxton Products, even during the mid 70’s when superchargers were not a major product line, the company commendably maintained product support for all it’s superchargers, including the McCulloch VS57’s (apart from that hiccup when they introduced the DO-VS59 in 1958) and to a lesser extent the VR57’s. This support included spare parts, rebuild kits and literature. In 1998 the Granatelli brothers split Paxton, selling off the supercharger and fuel systems divisions, and retaining the industrial blower division. The new owners, of the now named Paxton Automotive, junked most of the VS57 spare parts and units, and only supported the newer SN units. This support was short lived and as a part of a drive to concentrate on the more profitable supercharger sales, all rebuilds were outsourced to Craig Conley of Paradise Wheels in California. Further restructuring has now resulted in the merger of Paxton Automotive and Vortech during April 2001, and in June 2001 Paxton discontinued all SN series manufacture and support, focusing completely on the Novi gear driven units. In order to save the ball drive supercharger line Craig Conley (thanks Craig!) has bought out all of Paxton’s manufacturing rights, spares, jigs, moulds, etc., for the SN and earlier units, and anticipates further SN production in the near future.

As for Robert Paxton McCulloch, after the sale of Paxton Products in 1958 he expanded out into outboard engines, and in order to test these bought land adjacent to Lake Havasu in Arizona and built up Lake Havasu City. In 1962 he famously (or infamously over here as the mad American who thought he was buying Tower Bridge) bought London Bridge for $2.5 million dollars and shipped it back to Lake Havasu, where it was rebuilt across a part of the lake. The bridge rebuild was completed in 1971, and Bob McCulloch continued the development of Lake Havasu City until he passed away on February 25, 1977.